Price of stretch film

June 11, 2022

Does stretch film have an expiration date?

January 7, 2023Stretch film production common problems and solutions

You may have heard that in the countries that bought stretch film from Iran, after some time they did not want to buy this product from Iran, or they were mostly dissatisfied and complaining, do you know what is the reason for this?

In this article, we have analyzed and compiled an interview with the CEO of Aras Plastic Company about the reluctance of customers to buy again.

According to the investigations conducted by the marketing and sales team of Aras Plastic Company, after months of discussions and face-to-face meetings with customers who had encountered problems and did not want to buy Iranian stretch, the main problem was the lack of consistency in the quality of the products and the lack of Acceptance of this issue by stretch film manufacturers had been reported after its stabilization.

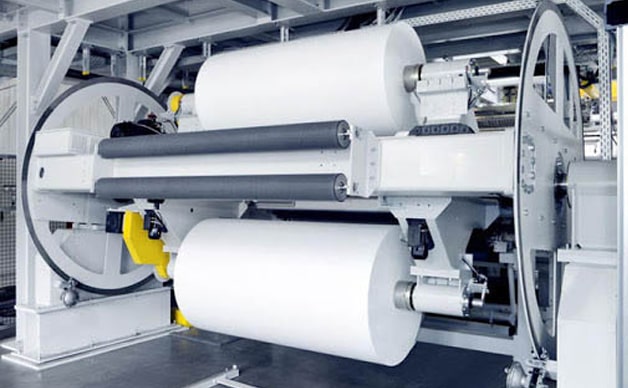

Certainly, no manufacturer has built his factory to produce a low-quality product, lack of sufficient knowledge, low-quality machines, use of old technologies, and most importantly, failure to examine the products that are the basis for comparing the manufactured product. Finally, they are the main causes of these problems.

Now we will review some examples of problems and defects expressed by customers in simple language:

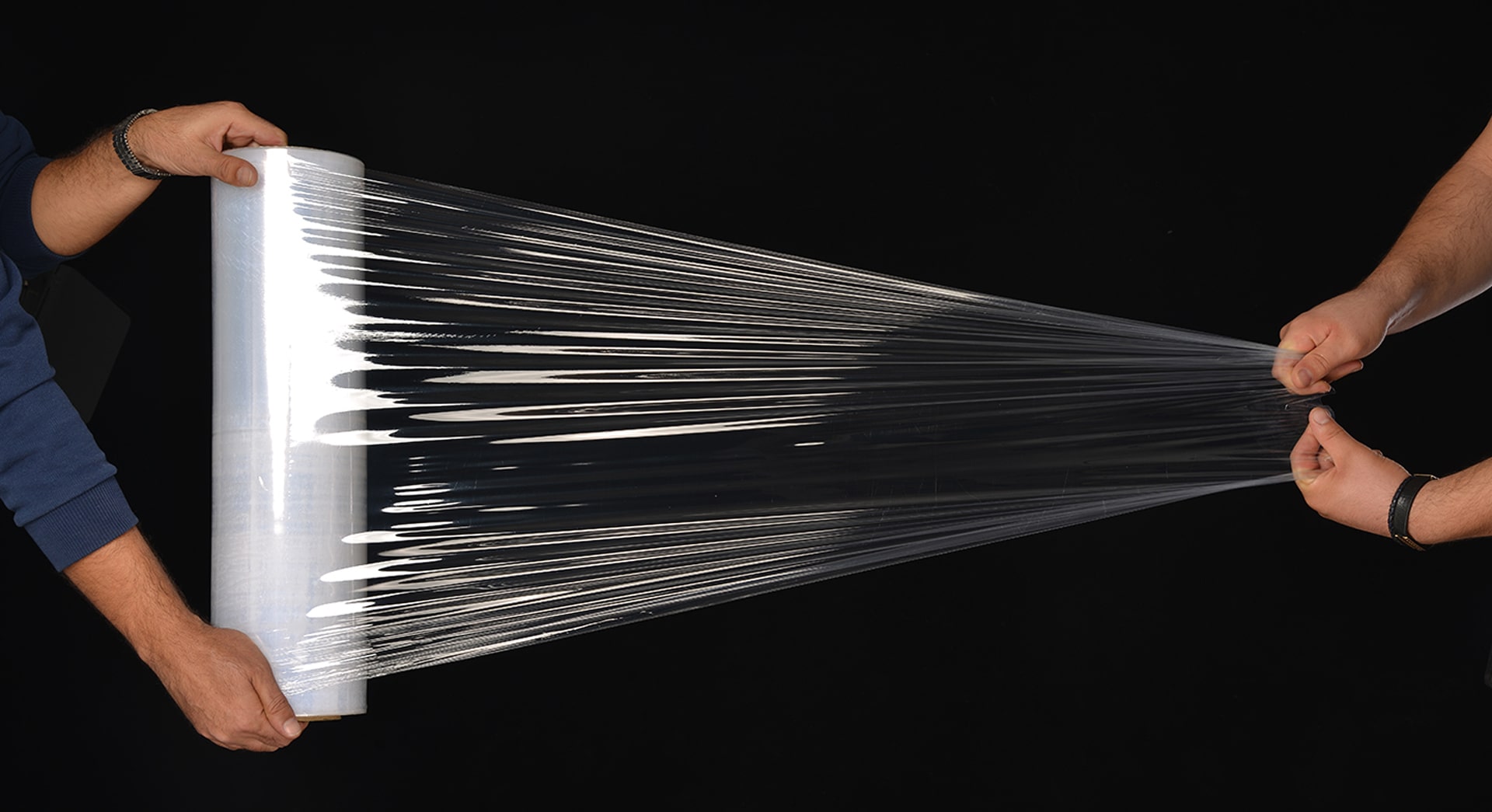

Iranian stretch films are torn in roll-to-roll machines at high speed.

This problem can come from several different parts:

Lack of proper packaging of rolls

Lack of proper cutting during production

Failure to use appropriate additives and interlayer adhesives

Using inappropriate and off-grade materials and waste granules

In the customer affairs department of Aras Plastic Company, all these cases have been fully checked and the final product has been reported with success and stretch film in roll-to-roll machines without any problems.

Iranian stretch films do not have a suitable and acceptable adhesion.

The issue of adhesion in stretch films is a very important and diverse issue, and the first question that arises is whether the manufacturer really adds glue to the stretch?

Are they not using this masterbatch because it is expensive?

The manufacturer added more than 20% glue in, but the product did not have glue at the time of use!

These are the questions that buyers have asked our experts about adhesion problems.

In answer to these questions, we must say that the idea that an adhesive is added to the last layer of the stretch film is completely wrong, and we must say that the term adhesive is used in a colloquial way, and the meaning of stretch adhesion is to reduce the molecular distance between polyethylenes, which causes The molecules are attracted to each other and finally the layers of the stretch film stick to each other. Now, to create this process, we need different additives, the combination of these additives needs to be changed according to the air temperature of the production, the air temperature of the consumer's place, the time of consumption of the product, etc. Weather and time conditions cause adhesion problems of stretch film.

At Aras Plastic, we have been able to solve the problems caused by adhesion with various tests and tailoring the production product to the time and place of consumption and by using the best additives and appropriate additives, and until today there has been no dissatisfaction from the export customers. there is not any report from our custmers in different countries.

Iranian stretche film stick to the cylinders during the roll-to-roll process and cause a decrease in the speed and tonnage of the output product.

Excessive use of inappropriate and low-quality PIB additive to create adhesion is the main cause of this problem.

To solve this problem, we in the Aras Plastic team have obtained a new formulation with the help of polymer engineers.

The stretch color produced by European factories is different from Iranian products.

Polyethylene which is used for the production of stretch film has a certain yellowness that Aras Plastic engineers have been able to solve this problem by adding special additives and the stretch produced in Aras Plastic does not have different with european countries.

The stretch films that we import from Iran have very good quality at the first time, but then there is lack of quality stability.

One of the questions that have been raised a lot in this regard is that the quality of stretch film is different in pallets. Even in one part which is 18 pallets, several stretch pallets have different quality.

The main issue that is very important in production is stability in production quality. Unfortunately, lack of attention to minor issues and lack of registration, control and standardization of production is one of the main causes of quality instability. That is, by registering and controlling manufactured products, you will achieve the desired result.

for example :

In Aras Plastic, during 24 hours, the temperature of the stretch film chillers, the temperature of the extruders, and the temperature of the environment are checked, changed and standardized in 3 stages, so that the output product materials melt at the same temperature and cool and become the product at the same temperature. According to the production statistics and reports, the temperature of the products produced in the night shift is 15 degrees and sometimes 20 degrees different, and according to the changes in the weather, all the changes are made.

The simplest problem is the combination and mixing of materials, which is done in factories by simple workers without any supervision and control using simple and manual mixers. The same composition and mixing of raw materials with additives is one of the most important and main factors. All these things are done in the production unit of Aras Plastic under the supervision of engineers and using up-to-date and appropriate mixers within a period of 1-2 hours for each combination.

Iranian stretch film micron is not fixed and has a very large micron tolerance, so that the weight of the rolls changes between 100 and 200 grams during roll to roll time.

One of the main causes of micron tolerance is the use of old machines and technologies, which Aras Plastic has been able to solve this problem for customers by using two new and advanced fully automatic production lines of 2019 and 2021 models.

In the above material, we examined some of the main concerns and problems of buyers of Iranian stretch films abroad, which were recorded by the marketing and sales team of Aras Plastic, and with the help of these data and information, we have been able to manufacture best stretch film as much as possible. Produced in Aras Plastic to bring it closer to the current European standards, according to the surveys conducted by Aras Plastic stretch film customers, it has a good quality and is equal to the stretch films produced in other countries. And most importantly, selling at Aras Plastic is not the end of the commitment, but the beginning of the commitment, and we assure our customers that whenever they have a problem related to production, we will solve the problem as soon as possible. Contact us for more information and to order all types of stretch film, including jumbo stretch, food stretch, industrial stretch, machine stretch, manual stretch film, furniture stretch film, and other stretch films.